Liquid Nitrogen Freezing Cabinet uses liquid nitrogen as a coolant to directly freeze food. The principle of liquid nitrogen freezing involves spraying low-temperature liquid nitrogen directly onto food. This method takes advantage of the low temperature (-196°C) achieved by vaporization of liquid nitrogen at atmospheric pressure and the high heat exchange coefficient of direct vaporization on the surface of the material. This process quickly and deeply freezes food. Currently, The liquid nitrogen freezing method is widely used in various applications, such as seafood, Whole Fish, Burgers, portioned meat, Processed fruits and vegetables, as well as the hardening of ice cream.

The cabinet-type liquid nitrogen blast freezer is equipped with multiple trays of stainless steel material. Liquid nitrogen is sprayed directly onto the surface of the material through nozzles. The material undergoes rapid freezing by exchanging heat with low-temperature nitrogen gas through fan-induced agitation in the tray. Vaporized low-temperature nitrogen gas is expelled through the exhaust port. To freeze 1 kg of food, Liquid nitrogen consumption ranges from 0,3 and 1 kg. Due to the short freezing time and the dependence on heat exchange by direct vaporization with liquid nitrogen, Dry consumption of frozen products is significantly lower compared to methods using air cooling.

- Product Details

- Characteristics

- Application

- Consultation

1. Material Support: Stainless steel rolling stock holder 304 with circulation system.

2. Refrigeration System: Liquid Nitrogen Vaporization Cooling System, Dual solenoid valve temperature control, Variable frequency dual fan cooling.

3. Isolation: The insulation layer consists of an aerogel insulation blanket and polyurethane foam insulation, with a thickness of 160 mm, providing excellent insulation and safety performance.

4. System: Uses a circulating liquid nitrogen atomization spray system imported from Germany.

5. Air Cooling Circulation: High-power fan with reinforced axial fan, Adjustable wind speed, ensuring fast and even freezing.

6. Control System: PLC Program Automatic Control System + touch screen, User-friendly input, Intuitive and reliable control, with temperature monitoring and alarm functions, to ensure safety.

7. Maintenance: The bottom of the equipment is equipped with a drain for easy cleaning and maintenance, Designed for long service life with low consumable consumption.

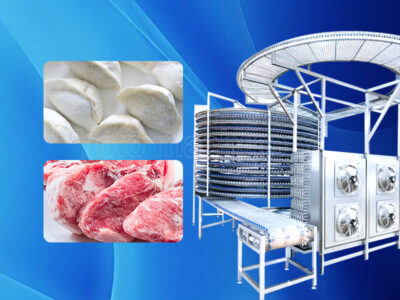

Seafood: Various seafood products, both raw and cooked, shelled and peeled seafood, various slices of fish, Soft-shelled seafood, sushi, etc.

Poultry & Meat: Diced products, slices or strips of raw or cooked poultry and meats.

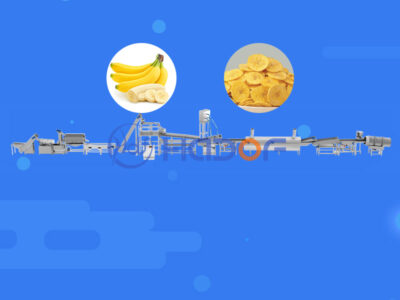

Fruits: Strawberries, Pineapples, papayas, Handles, longans, Durians, Lychees, All in dice, slices or whole fruits.

Vegetables: Diced or sliced vegetables, Sweet corn kernels, Fresh beans, pea pods, herbs (like frozen spinach).

Dairy/Grains: Pastry, Individually packaged pasta, Tofu Blocks, Tofu skin, etc.

Previous: Tunnel Blast Freezer

Next: Spiral blast freezer

Yoto Food Processing Machines.

Yoto Food Processing Machines.