This set of potato chip production line is designed to handle various stages of the manufacturing process, from raw potatoes to final packaged potato chips ready for distribution and consumption. The whole line is mainly composed of elevator feeder, Stone Removal Roller Cleaning Machine, Brush Peeling Machine, Cutting Machine, Air Bubble Cleaning Machine, rotary type continuous frying machine, drum flavoring machine and automatic type packaging machine 420.

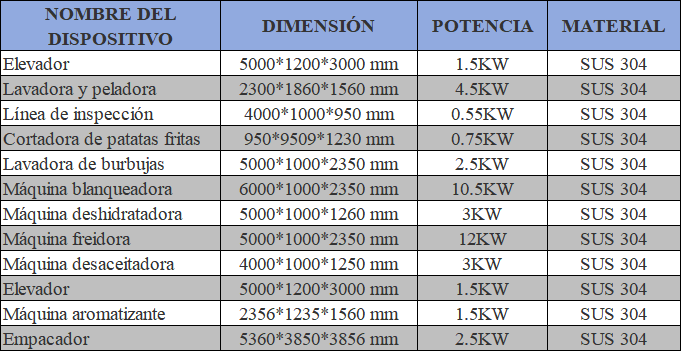

Production Line Equipment

1. Elevator: Used for lifting and transporting materials. The potatoes can be easily poured into the hopper manually and the material can be lifted continuously and evenly to the next process via the conveyor belt, which saves a lot of work and is convenient and practical.

2. Cleaning & Peeling Machine: Potatoes that come in can be cleaned and peeled, and materials are fed and discharged at the same time, allowing you to work continuously.

3. Sorting Ribbon: To Choose and Repair Cleaned and Peeled Potatoes. If there's any bad, must be selected.

4. Potato slicer: Place the peeled and cleaned potatoes continuously in the feed port, And the fries will be automatically cut.

5. Washing machine: Washing the starch from the French fries.

6. Bleaching Machine: Blanch and fix the color of the fries, and add food additives.

7. Cooling Machine: Chill the blanched fries to avoid sticking.

8. Air-cooled dehydrator: Dry the moisture on the surface of blanched frying fries.

9. Frying machine: Frying the fries. The temperature can be controlled automatically and can be worked continuously.

10. Deoiling Machine: Removing the oil from the surface of the French fries.

11. Sorting Ribbon: blowing the fries to cool them for packaging and selecting the unsuitable fries.

12. Seasoning Machine: Season Selected Potatoes.

13. Packaging Machine: Packing the fries.

Yoto Food Processing Machines.

Yoto Food Processing Machines.