The fully automatic granule packaging machine is composed of a bagging machine, A smart combination scale, a Z-shaped lift and a work platform. It is mainly suitable for fully automatic packaging of various solids, Granules & Block Materials, such as expanded foods, Snacks, nuts, melon seeds, Almonds, Pistachios, Pine nuts, candies, Jellies, Bean Products, Frozen food, Pet Food, Small Hardware Materials. Can feed materials automatically, Automatically take out bags, encode, Opening Bags, Quantitative Filling, Exhaust/Nitrogen Filling.

- Product Details

- Characteristics

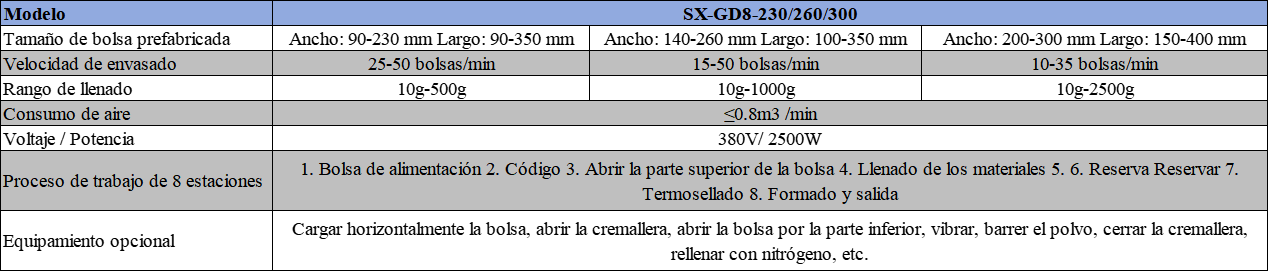

- Parameters

- Consultation

1. It adopts Siemens German PLC control and is equipped with an easy-to-use touch screen human-machine interface control system for easy operation.

2. Variable Frequency Speed Adjustment: This machine uses a variable frequency speed adjustment device, allowing speed adjustments within a specified range.

3. Auto-detect function: If the bag is not open or is not properly opened, It will not feed and will not be heat-sealed. And the bag can be reused, saving materials and production costs.

4. Safety Device: An alarm will be triggered when the working pressure is abnormal or when the heating tube malfunctions.

5. Quick change of packaging bag specifications: The width of the mechanical handheld device can be easily and quickly adjusted.

6. Equipped with a random security door made of tempered glass, The machine stops immediately when the door is opened, Ensuring the safety of operators.

7. Use an oil-free vacuum pump to avoid polluting the environment.

8. Wide Packaging Range: Different measuring devices can be selected, making it suitable for packaging liquids, sauces, granules, powders, irregularly shaped materials and much more.

Yoto Food Processing Machines.

Yoto Food Processing Machines.