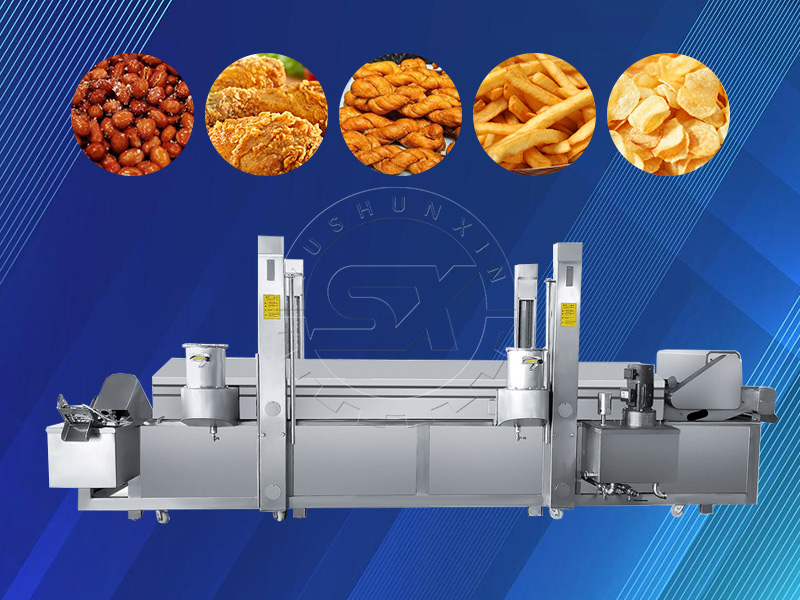

The continuous fryer is made of stainless steel, which guarantees its durability and robustness. The inner frying container can be lifted with a single touch, making cleaning the frying chamber exceptionally comfortable. Conveyor belt operates at adjustable variable speeds, which allows the frying time to be adjusted and the temperature to be controlled according to the different materials being fried. Uses electric heating, achieving an efficiency index higher than 95%, with the consequent energy savings.

Equipped with a fully automatic oil filtration system to remove oil residues, It also has an automatic slag scraping system, which allows the sediment accumulated at the bottom of the fryer to be removed in time. This ensures that there are no charred particles in the oil, preventing blackening and extending its useful life. As a result, Fried products have a bright color, excellent texture and higher product quality, all while reducing costs.

- Product Details

- Characteristics

- Consultation

1. Double-layer mesh structure, Prevents flotation of materials, so that both sides of the materials can be fried. The oil temperature is adjustable from normal temperature to 300°C.

2. Equipped with auto-lift function: Mesh tape can be lifted for easy cleaning and maintenance.

3. The temperature can be adjusted according to the fried product, Temperature control is precise, and the temperature in the whole frying machine is uniform.

4. Oil circulates through the filtration system, which can filter out most of the oil residues and greatly prevent the oil residues from fixing and damaging the oil.

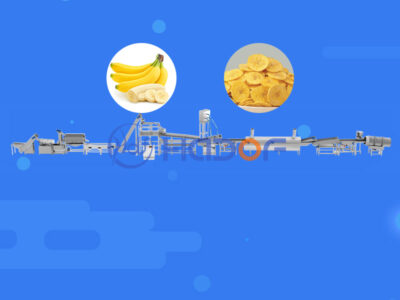

5. The machine is mainly used in the production line. According to the product selection before and after the equipment, to achieve automatic production.

Previous: Multifunctional Bubble Cleaning Machine

Yoto Food Processing Machines.

Yoto Food Processing Machines.